ReAssure™ Next Generation Monitoring from Planer

Features

- Scalable - monitoring of 1 sensor up to a thousand sensors

- Cost Effective - uses existing IT infrastructure

- Low Maintenance - Automatic logging of multi-parametric logging data

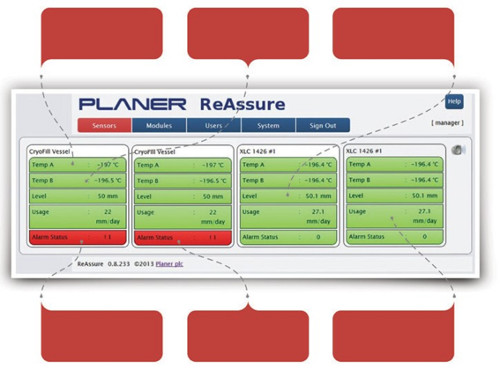

- Intuitive - one screen to display system status

- Accessible - secure access to monitoring data via web interface

- Extensive - monitoring a variety of parameters with over 50 sensor options

- Unique - the first monitoring solution to record per chamber CO2 from benchtop incubators

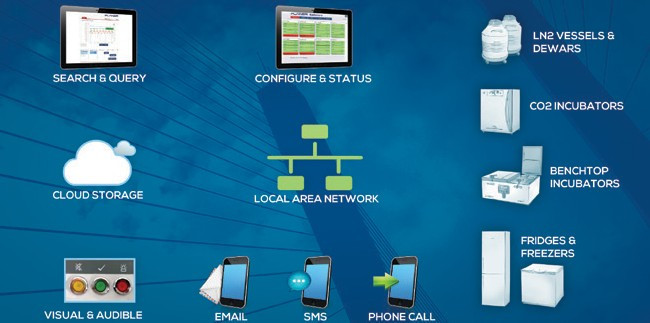

The ReAssure monitoring solution from Planer offers laboratories and organizations of all sizes an intuitive, scalable and compliant monitoring solution for a wide range of environmental parameters.

Based on over 40 years experience in monitoring and controlling the environmental conditions for high value biological materials, ReAssure is centered on best-in-class sensing technology. The solution includes options for compliant data storage and reporting combined with a wide choice of sensors including CO2, O2, humidity, pH, door status and temperature for a variety of laboratory devices.

ReAssure offers a cost effective and flexible way to protect precious materials and ensure rgulatory adherence. Adaptable from one monitoring point to a thousand - ReAssure offers a modest ID footprint and unrivalled secure accessibility through an intuitive web-based interface.

Users also have the option to benefit from compliant storage of historical monitoring data, enabling comprehensive searching and reporting of environmental conditions, combined with annotations and context. This enables users to report by exception - detail all alarm events over a predefined duration - at the touch of a button.

Monitoring data can also be exported as a PDF report or to CSV format for subsequent analysis.

Per Chamber CO2 Monitoring for Benchtop Incubators

It is well understood that all incubators suffer some loss of gas from source to chamber - as much as 0.5% in some cases.

Moreover, no technology exists to monitor the per chamber CO2 concentration - until now.

The ReAssure monitoring solution offers a retrofittable infra red (IR) based CO2 sensor for leading benchtop incubators, including the Planer PLBT37. Mounted on the side of the incubator, high specification nafion tubing is connected to the exhaust ports at the back of each chamber, which in turn supply two independent IR sensors.

This information is recorded directly into the ReAssure Configure and Status unit. When combined with other relevant parameters (chamber temperature, ambient temperature, ambient humidity) users are provided with a comprehensive view of environmental conditions and can ensure the best possible culture conditions.

Fluorescent pH Monitoring for Big Box Incubators

- Cost Effective - less expensive than existing fluorescent pH monitors

- Low Maintenance - no calibration required with simple sensor replacement

- Clean - disposable, sterile low cost sensor

- Innovative - based on leading edge sensing technology

Traditionally, pH monitoring for larger incubators using fluorescent sensors has proved expensive. The alternative of using a pH meter is time consuming through the requirement of regular calibration.

Traditionally, pH monitoring for larger incubators using fluorescent sensors has proved expensive. The alternative of using a pH meter is time consuming through the requirement of regular calibration.

The new pH SAFE™ sensor technology provides a cost-effective way to enable continuous logging of pH levels without the requirement for frequent calibration. Using a sterile fluorescent, pre-calibrated probe combined with sophisticated sensing optics, users can provide uninterrupted monitoring of pH at a fraction of the cost of existing techniques. The inexpensive consumable probe remains stable for up to 6 days after which it can be easily replaced.

Temperature Monitoring Options

ReAssure offers a range of temperature sensors including: ribbon sensors for the independent monitoring of benchtop incubators, ultra thin sensors for temperature logging in equipment without access ports, as well as specialized probes for liquid nitrogen dewars which can record both temperature and level.

ReAssure offers a range of temperature sensors including: ribbon sensors for the independent monitoring of benchtop incubators, ultra thin sensors for temperature logging in equipment without access ports, as well as specialized probes for liquid nitrogen dewars which can record both temperature and level.

Ultra Thin Temperature Sensors

This unique option for ReAssure allows temperature monitoring (-200° C to +200° C) in equipment that lacks probe access ports. With dimensions of 6.35 mm x 13 mm x 1.3 mm, this sensor can enable temperature monitoring in a variety of devices without the requirement for drilling an entry point.

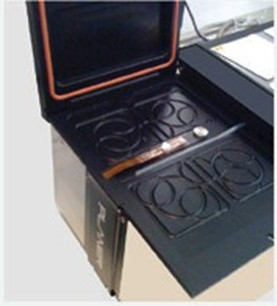

Independent Monitoring of Benchtop Incubators

The ribbon temperature sensor is designed to record chamber temperatures in a benchtop incubator. The ribbon assembly enables the probe to be fed directly into the culture chamber and allows the chamber lid to be securely closed. With a measurement range of -200° C to +200° C this option provides a means of independently monitoring benchtop incubator temperature without having to utilize access ports.

The ribbon temperature sensor is designed to record chamber temperatures in a benchtop incubator. The ribbon assembly enables the probe to be fed directly into the culture chamber and allows the chamber lid to be securely closed. With a measurement range of -200° C to +200° C this option provides a means of independently monitoring benchtop incubator temperature without having to utilize access ports.

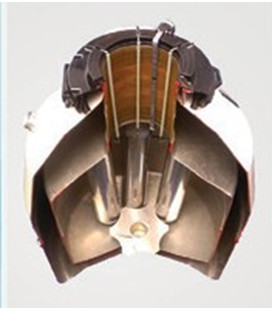

Combined temperature and level monitoring for liquid nitrogen vessels

Available in a range of sizes to fit a variety of different storage vessels, this high accuracy (± 0.3° C) platinum sensor is attached to a stainless steel band and formed along the internal contours of the dewar. This approach removes the necessity for cork drilling or strapping of the sensor assembly. Furthermore, installation can be performed on vessels while in use without disruption to the stored samples.

Vessel Controllers as Part of the ReAssure Monitoring System

High end controllers, like the Chart TEC 3000 and the more recent CryoFill unit, can also be included as part of a ReAssure monitoring solution. Controller status is easily visible on the ReAssure screen, providing users a complete overview of their vessel controllers.

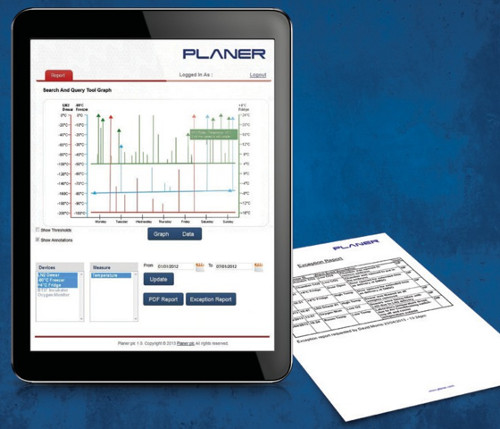

ReAssure Search and Query

Users of the ReAssure system have the option to include cloud-based storage as part of their monitoring solution.

With this configuration, monitored data is automatically sent, via email, to a secure and encrypted off-site location without the requirement for user intervention.

Using the ReAssure Search and Query web interface, users can report on historical monitoring information including details of all alarm events in a predefined date range, with associated annotations, at the touch of a button. The ability to rapidly detail all alarm events, together with associated annotations, significantly reduces regulatory burden. The ability to trend monitoring data over time can provide a useful predictive tool to identify potential equipment failures.

Available Models

|

Product Code

|

Description

|

|

PLGDRA-CFG+ST-PRO

|

ReAssure Monitoring System, Configure up to 50 Sensors, Each

|

Options

|

Product Code

|

Description

|

|

PLGDRA-CFG+ST-PRO-UNIT

|

Additional Servers for PLGDRA-CFG+ST-PRO System, 50 Sensors per Server, Each

|

|

PLGDRA-CFG+ST-LITE

|

ReAssure Lite Monitoring System, Configure up to 50 Sensors, Each

|

|

PLGDRA-SEAR-QUERY

|

Search and Query Interface (Requires Full Configure & Status) for PLGDRA-CFG+ST-PRO Unit, Each

|

Accessories

|

Product Code

|

Description

|

|

PLGDFCSL-SD2-UK

|

Alarm Output: Direct Phone Line Autodialler (UK Tested Only), Each

|

|

PLGDKRYO-WATCHDOG

|

Visual & Audible Alarm with Relay Output, Each

|

|

PLFPLG60T-SCHUKO

|

Battery Backup - provides 30 minutes of Power, Each

|

|

PLFPLG60T

|

Battery Backup - provides 30 minutes of Power, Each

|

|

PLGDKRYO-BASE-PRT7

|

Module for Sensors, Takes 7, Requires Mains Socket, Each

|

|

PLGDTP10-04

|

Temperature Sensor for Fridges & Freezers (-200° C to 35° C). Requires Connection to 1 input of PLGDKryo-Base-PRT7, Each

|

|

PLGDTLP-03

|

Temperature Sensor for LN2 Dewars Temperature/Level. Requires connection to 1 input of PLGDKryo-Base-PRT7, Each

|

|

PLGDTLP-03-750

|

750 mm Long Probe for Larger LN2 Dewars Temperature/ Level. Requires connection to 1 input of PLGDKryo-Base-PRT7, Each

|

|

PLGDTP10-04-FEP

|

3.4 mm Diameter LN2 Vessels, Each

|

|

PLPR101546

|

Heated Stages, ICSI rigs, surfaces and Incubators without Access Ports. No connector on probe, need to wire to module, Each

|

|

PLPR102110

|

Temperature Sensor for PLBT37 and Standard Incubators with Access Ports. No connector on probe. Need to wire module.

|

|

PLPRGDTP10-04-D-MINC

|

Temperature Sensor for Minc Incubators, Each

|

|

PLPR100391

|

Temperature Sensor for Room Temperature, Each

|

|

PLGDKRYO-BASE-STATUS

|

6-Channel Digital Input/Output Sensor Module, Each

|

|

PLSW101492

|

Door or Lid Switch Sensor Module, Each

|

|

PLGDKRYO-BASE-ANALOGUE

|

8-Channel Analogue Input Sensor Module, Each

|

|

PLGDREASSURE-CO2-OR

|

CO2 Kit for PLBT37, Each. Includes:

- 1 x PLGDKRYO-CO2-BT37

- 1 x PLGDKRYO-BASE-ANALOGUE

- 1 x PLGDRACFG+ST-LITE

- 1 x PLGDRA-SUPPORT-LITE

- 1 x PLGDRA-SEARCH-QUERY

|

|

PLGDKRYO-CO2-BT37

|

CO2 Sensors for PLBT37. Requires Power Supply (AP009619 is suitable), Each

|

|

PLFBCSI62000

|

pH Meter Sensor for Big Box Incubators with access ports. No sensors included, will need to order PLFBCSI400003, 10 Sensors/Pack

|

|

PLGDKRYO-CO2ADV

|

CO2 Sensor for Incubators with Access Ports, Each

|

|

PLGDKRYO-CO2ADV-FLAT

|

CO2 Sensor for Incubators without Access Ports, with Flat Cable, Each

|

|

PLFBCSI62000

|

pH Meter for Big Box Incubators with Access Ports, Each

Requires PLFBCSI400003 Sensors (Sold Separately)

|

|

PLFOMNEE31-RH-T-FAST

|

Humidity and Temperature for Incubators with Access Ports, Each

|

|

PLGDKRYO-DIFF-PRESS

|

Differential Pressure Sensor, Each

|

|

PLFOMNEE66-VC-D02

|

0-2 mps Flow Meter, Each

|

|

PLFOMNEE10-FT-D04--

|

Room Temperature + Humidity Sensor with LCD Display, Each

|

|

PLFOMNEE10-T6-D04

|

Room Temperature Sensor with LCD Display, Each

|

|

PLFOMNEE10-F6D04--

|

Room Humidity Sensor with LCD Display, Each

|

|

PLFANXO2-115BRUK10Y420

|

Room Oxygen Monitor, 115 Volts, Each

|

|

PLGDKRYO-BASE-MODBUS

|

Connect 32 Modbus Devices, Includes Cable for 1 Device, Each

|

|

PLAC102086

|

Daisy Chain Cable for Modbus/Tec 3000, Each

|

|

PLGDKRYO-BASE-PRT7-STAT

|

7 Channel Temperature and 8 Channel Analogue Input, Each

|

|

PLFBCSI400003

|

pH Sensors (Factory Calibrated), 10/Pack

|

|

PLFBCSI332400005

|

Quality Control device (One per facility - QC2 Standard, Each

|

|

PLFANX9100-1020

|

Replacement Oxygen Sensor for Calibration Purposes, Each

|

|

PLME101462

|

Fine Control Valve for Calibration Purposes, Each

|

|

PLAY100919

|

Analog Oxygen Calibration Starter Kit, Each

|

|

PLAY100920

|

Vaisala CO2 Calibration Starter Kit, Each

|

|

PLCN100916

|

Calibration Gas - CO2 5% Balance N2, Each

|

|

PLCN100917

|

Calibration Gas - 100% N2, Each

|

|

PLCN101463

|

Calibration Gas 24% O2. Balance N2, 34 Litres/Unit

|

|

PLFVSHM70C0E1A0AB

|

RH and Temperature Meter and Probe. Measures from -70° - +180° C, Each

|

|

PLFVSHM70A0E1A0AB

|

RH and Temperature Probe. Measures from -70° - +180° C, Each

Meter sold separately

|

|

PLFVSGM70A0A1L0A0B

|

CO2 Probe, 0-10%, Meter sold separately

|

|

PLFVSGM70C0A2L0A0B

|

CO2 Meter and Probe, 0-10%, Each

|

|

PLFVS19040GM

|

Serial Adapter Cable, Each

|

|

PLGDHH-INC-01

|

Handheld Monitor for Controlled Rate Freezers and other Low-Temperature Equipment, Each

|

Specifications

|

Reassure Lite

|

Reassure

|

|

|

Up to 50

|

Up to 1,000

|

Number of Sensors Supported

|

|

Yes

|

Yes

|

Local data logging

|

|

Yes

|

Yes

|

Temperature

|

|

Yes

|

Yes

|

O2

|

|

Yes

|

Yes

|

Door status

|

|

Yes

|

Yes

|

Environmental CO2

|

|

Yes

|

Yes

|

Benchtop Incubator CO2

|

|

Yes

|

Yes

|

LN2

|

|

Yes

|

Yes

|

Pressure

|

|

No

|

Yes

|

Compliant 'cloud' storage

|

|

No

|

Yes

|

User definable searching

|

|

No

|

Yes

|

Exception reporting

|